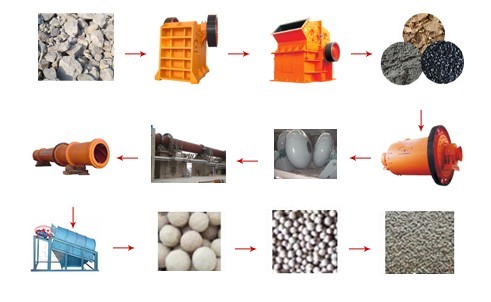

Ceramsite sand production line is designed completely according to the properties and production requirements of ceramsite sand, mainly through taking a variety of steps to produce ceramsite sand. The main key processes in the whole process flow are crushing stage, fine crushing stage, screening stage and roasting stage, which are indispensable.

Highlight advantages

The allocation is scientific and reasonable. The ceramsite sand production line is carefully designed considering the needs of users, so that each equipment can play its role. All equipment plays an indispensable role in the production line. The configuration of the whole production line is scientific and reasonable, and the investment is ideal.

Equipment cooperation is tacit. All the equipment model parameters of all production lines have been studied and formulated, which makes all the equipment cooperate with each other. The overall design of the production line is reasonable and the production process is smooth.

High efficiency of finished products. The whole process design of the production line is mature. The ceramsite sand produced by the production line has high economic benefits, the finished products are widely sold in the market, and the application fields are also very wide. The economic value of the materials is improved and its potential value is developed.

Low energy consumption and low cost. The production line adopts sleeve drying structure, which can make full use of heat energy in production, and increase the original 30% heat energy utilization rate to about 70% by using the heat lost from the cylinder wall. For the rotary kiln with cylinder diameter of about 2.5m, the energy cost can be saved by 450000-500000 / year.

Process flow of ceramsite sand production line

The bulk materials are cleaned and decontaminated by the stone washer, and then preliminarily broken by the jaw crusher, and then finely broken by the hammer crusher, so that the discharge particle size is less than 5mm; after the crushing, the materials are sent to the storage bin by the bucket elevator, and then evenly and quantitatively fed into the Raymond mill for grinding through the vibration feeder, and then sent to the silo to store the trapped materials.